What are the Mechanical Properties of Aluminium?

From soda cans to aircraft, kitchenware to construction, aluminium is one of the most widely used metals. In its versatility, it is next only to steel. Aluminium is also the world’s most abundant metal. It is the third most common element comprising 8% of the earth’s crust. In its raw form, aluminium is found in the mineral bauxite. From that, using various processes it is converted into aluminium oxide (alumina) and finally, to aluminium metal.

Mechanical properties of aluminium are mainly defined in terms of the material reacting on the applied load including the relationship between stress and strain. The mechanical properties of aluminium are:

- Tensile strength: This is the amount of load or stress that can be handled by a material before it stretches and breaks. Tensile strength is the material’s capacity of resistance to tension that is caused by mechanical loads applied to the material. For aluminium extrusion manufacturers, the ability of it to resist breaking or failing under tensile stress while it is stretched or pulled is one of the most important and widely appealing properties. The tensile strength of pure aluminium is around 90 MPa but this can be increased to over 690 MPa for some heat-treatable alloys.

- Yield stress: Yield strength or yield stress is the stress a material can withstand without permanent deformation. It is a point at which it will no longer return to its original dimensions and is the practical approximation of the elastic limit. Yield strength is often used to calculate the maximum permissible load in a mechanical part. Any deformation caused by a stress greater than the yield strength is irreversible. Yield strength is expressed in terms of N/m2 or pascals. Yield strength is a very important criterion for controlling the production techniques of aluminium players.

- Modulus of elasticity: This is the ratio of the stress in a body to the corresponding strain. Stress and strain have a proportional relationship. When force is applied on the metal, it will be strained and will elongate in the direction of the force. However, if the force is removed, it will return to its original length. This is called elasticity. If the magnitude of force is exceeded, it will cause the substance to not be able to return to its original length upon removal of the force. If the modulus is higher it means the metal is stiffer and is measured in GPa’s.

- Endurance strength: The fatigue limit or endurance strength (Se) is the stress level below which an infinite number of loading cycles can be applied to a material without causing fatigue failure. If the stresses applied to the material are low enough, then the material will not experience fatigue under repeated cyclic loading. Aluminium does not have an endurance limit such as ferrous metals and will fail if it goes through enough stress cycles. However, it may be thousands or even millions of cycles before Aluminium fails depending on the load or cycles.

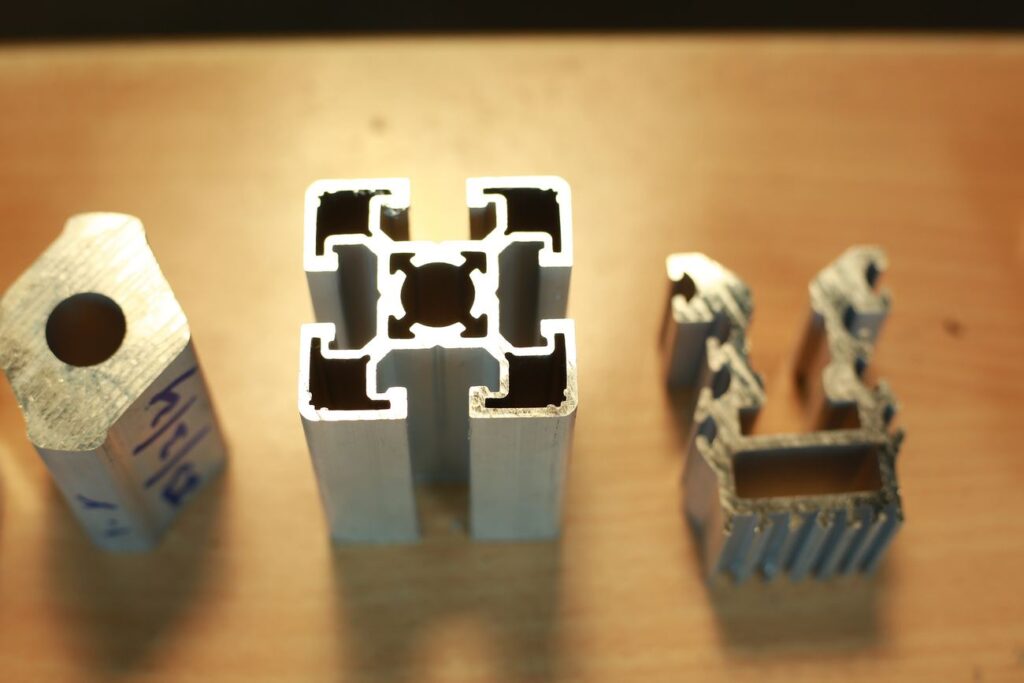

- Elongation at break: which is also known as fracture strain, is the ratio between changed length and initial length after breakage of the test specimen. The value would differ widely for a thin sheet, plate and aluminium extrusions. It expresses the capability to resist changes of shape without crack formation. The magnitude of the elongation depends on the cross-sectional dimensions of the sample used.

- Hardness: Pure aluminium is soft and mineral elements must be added to pure aluminium to make it stronger. These additional elements not only improve the hardness of aluminium metal but also improve its corrosion resistance. Aluminum fabricators of Chennai like KMC Aluminium which can be considered the best aluminum company in Chennai have a very elaborate testing lab to test the hardness and the chemical composition (Spectro).

The exceptional ability for aluminium to form alloys expands its reach across industries and applications. As Tamil Nadu’s leading manufacturer of aluminium profiles, KMC Aluminium has been consistently Number 1 for close to a decade. Do get in touch with us for your requirements for extruded aluminium products.

#BestAluminiumCompanyInChennai #aluminiumcompany #aluminiumextrusionmanufacturers #aluminiumfabricatorsinchennai