The Role of Aluminium in Electric Vehicle Battery Enclosures

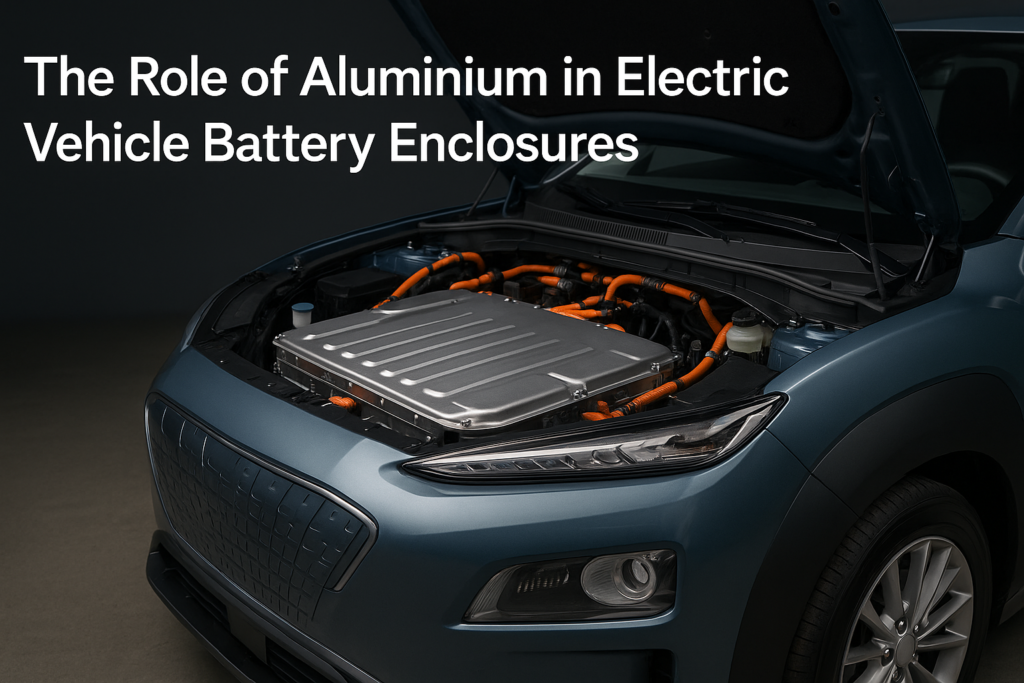

The electric vehicle (EV) industry is rapidly transforming the global automotive landscape. As EV adoption increases, manufacturers are re-engineering vehicle platforms to improve safety, efficiency, and performance. At the heart of this transformation lies a critical structural component – the electric vehicle battery enclosure.

Battery enclosures are no longer simple protective casings. They are structural, thermal, and safety-critical elements of modern EV architecture. At KMC Aluminium, we understand how material choice and manufacturing precision directly impact the performance of these enclosures. Aluminium has emerged as the preferred material — and for good reason.

Why Battery Enclosures Are Critical in EV Design

An EV battery enclosure must perform multiple functions simultaneously:

-

- Protect battery cells from mechanical impact and vibration

-

- Maintain structural integrity during collisions

-

- Enable efficient heat dissipation and thermal regulation

-

- Resist corrosion and environmental exposure

-

- Support lightweight vehicle design for improved range

Meeting all these requirements demands a material that is light, strong, thermally efficient, and manufacturable with high precision. Aluminium satisfies all these conditions — making it indispensable in EV battery enclosure design.

Aluminium’s Advantages in EV Battery Enclosures

Lightweight Performance That Enhances Driving Range

One of the biggest challenges in electric vehicle engineering is weight reduction. Heavier vehicles consume more energy, reducing range and efficiency. Aluminium offers an outstanding strength-to-weight ratio, delivering structural robustness at significantly lower weight compared to traditional materials like steel.

By using aluminium extrusions and profiles for battery enclosures, EV manufacturers can achieve meaningful weight savings without compromising safety — directly improving vehicle range and energy efficiency.

High Structural Strength and Crash Safety

EV battery packs must remain protected even during severe impact events. Aluminium’s ability to absorb and dissipate crash energy makes it ideal for battery enclosure structures. Engineered aluminium profiles can be designed with controlled deformation zones that manage impact forces while protecting the battery cells.

At KMC Aluminium, our extrusion expertise allows precise control over cross-sectional geometry — enabling enclosure designs that balance rigidity and energy absorption for enhanced crash performance.

Superior Thermal Management Capabilities

Battery temperature directly affects EV performance, safety, and battery lifespan. Aluminium’s high thermal conductivity enables efficient heat transfer away from battery cells, supporting consistent temperature control.

Aluminium enclosures can integrate cooling channels, heat paths, and mounting features directly into the extrusion design. This reduces the need for additional components while improving overall thermal efficiency — a critical factor in high-energy-density battery systems.

Corrosion Resistance for Long-Term Durability

Battery enclosures are exposed to moisture, road salts, dust, and changing weather conditions. Aluminium naturally forms a protective oxide layer that resists corrosion, making it well-suited for underbody and chassis-mounted applications.

With additional surface treatments such as powder coating or anodizing, aluminium battery enclosures deliver long-term durability and minimal maintenance – even in demanding operating environments.

Precision Manufacturing for Complex Enclosure Designs

Modern EV platforms demand compact, modular, and scalable enclosure designs. Aluminium extrusion offers unmatched design flexibility, allowing complex cross-sections, reinforcement ribs, mounting interfaces, and sealing channels to be manufactured as a single profile.

At KMC Aluminium, precision extrusion and CNC machining enable tight dimensional tolerances – ensuring accurate fitment, reliable sealing, and faster assembly at the OEM level. This reduces part count, simplifies production, and improves overall system reliability.

Aluminium and Sustainability in Electric Vehicles

Sustainability is central to electric mobility — and aluminium aligns perfectly with these goals. Aluminium is 100% recyclable without loss of mechanical properties. Recycled aluminium requires significantly less energy than primary production, reducing overall carbon footprint.

By choosing aluminium battery enclosures, EV manufacturers support circular manufacturing practices and contribute to lower lifecycle emissions — reinforcing the environmental promise of electric vehicles.

The Role of KMC Aluminium in EV Applications

With strong expertise in aluminium extrusion, machining, and value-added processing, KMC Aluminium supports industries that demand precision, consistency, and performance. Our manufacturing capabilities enable the production of aluminium profiles suitable for structural automotive applications, including EV battery enclosure systems.

From controlled billet processing and extrusion to machining and finishing, we focus on delivering profiles engineered for real-world performance – where safety, tolerance, and reliability are non-negotiable.

Future Outlook: Aluminium in Next-Generation EV Platforms

As EV platforms evolve, battery enclosures will become increasingly integrated into the vehicle’s structural architecture. Aluminium will continue to play a central role – not just as a housing material, but as a key contributor to strength, efficiency, and safety.

Advancements in aluminium alloys, extrusion techniques, and joining technologies are enabling lighter, stronger, and more efficient battery enclosures — paving the way for the next generation of electric mobility.

Conclusion

Aluminium has become a cornerstone of modern electric vehicle battery enclosure design. Its lightweight strength, crash performance, thermal efficiency, corrosion resistance, and sustainability make it the material of choice for EV manufacturers worldwide.

At KMC Aluminium, we remain committed to engineering aluminium solutions that support the future of electric mobility – delivering precision-crafted profiles designed to perform where it matters most.

Recent Comments