The Metal of the Future

The “Aluminium Age” is here, and how! As this metal is getting increasingly widespread, more people are now realising the value and versatility of it. Over the past few years, KMC aluminium

company, Tamil Nadu’s leading expert, has been providing services in the world of aluminium. At KMC, we employ a 5-step process which is in accordance with ISO standards. At our aluminium factory, we ensure that our highly qualified and trained crew review our materials and that our final products are double-checked at every stage of production – we also take special care to guarantee the durability and finish of our products. This has resulted in us exceeding the expectations of our clients time and again and has won us many laurels for the same.

At KMC, we use modern facilities and the latest imported machinery and produce about 700 tons of aluminium extruded products per month.

Quality First

At KMC, we take great pride in our control measures and ensure maximum reliability and durability of any product that has our name associated with it. In addition, our company also

gives an assurance of high-quality aluminium products at great speed and offers excellent scope for processing aluminium reforming activities. The end products are made without compromising on quality and safety.

KMC adheres to the highest standards of quality in all unit practices and operations. We follow the National Aluminium Company Limited(NALCO) price.

Products & Application

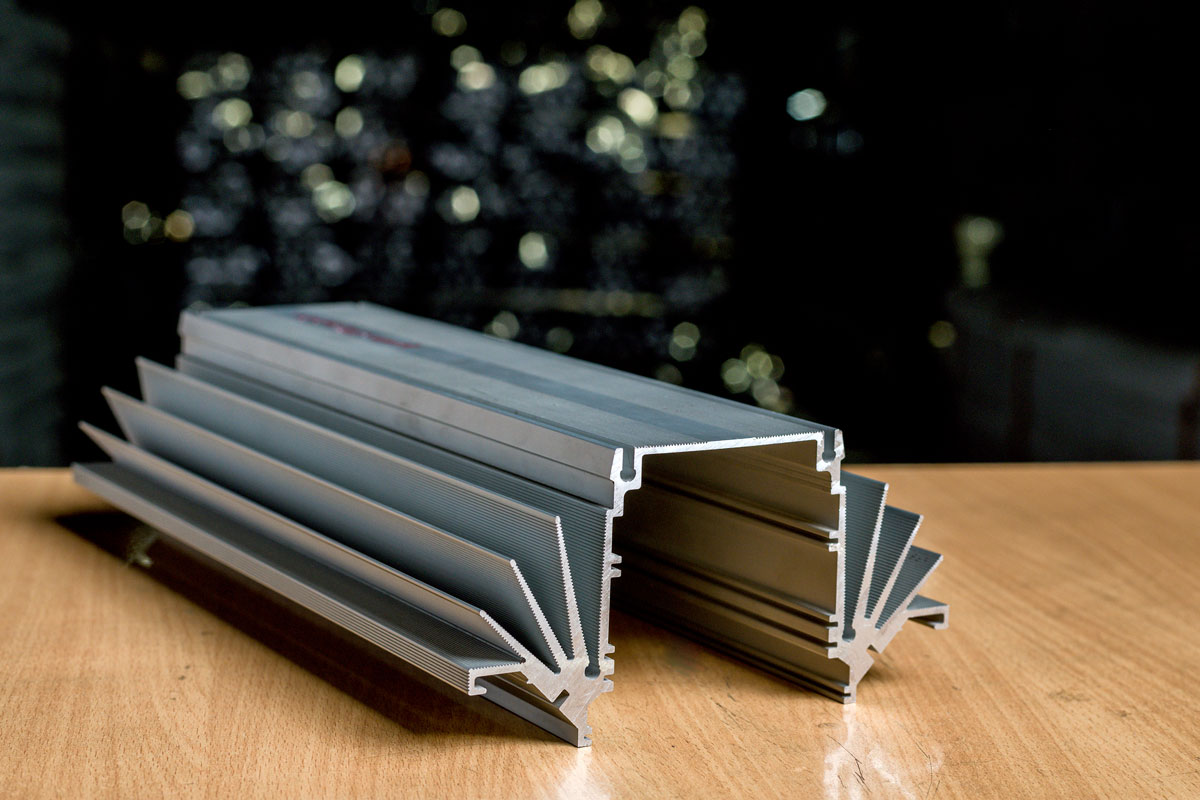

KMC is one of the Tamil Nadu’s best aluminium profile manufacturers – our products have a wide range of applications like A/C & house grills, solar panels, heat sinks, fencing, ladders,

electronic cars, buses, railway doors & frames and glazed surfaces for architecture. We also manufacture aluminium sheets.

Value Edition

KMC, being aluminium suppliers, customises aluminium frames and fabricates it depending on the customer’s needs. KMC, as the extruder, gives the semi-furnished customised product to

other aluminium suppliers until it reaches KMC back again. In a few months, we are starting value edition of our own, which involves processes like aluminium machining, aluminium profile

welding and aluminium profile bending.

Aluminium Extrusion

The life of our extruded aluminium products starts from the raw material stage where we use only premium quality aluminium.

As the best aluminium extrusion manufacturers, KMC has this process flow:

- Furnace

- Billet Cutting

- Continuous Billet Heating

- Die Heating oven

- Extrusion Press

- Transfer Table Conveyor

- Stretching & Straightening

- Cutting

- Aging

- Packing & Dispatching

The main motive of KMC Aluminum is to maintain world-class standards, provide customised solutions and also meet the growing demands of our valuable customers. The satisfaction of our

customers is the reason why we are the top aluminium manufacturers in Tamil Nadu. The KMC name stands for quality, quantity, quick service, reliability & durability today, tomorrow and in the years to come!